- CALWAVE CASE STUDY

UC Berkeley Startup Catches Wave Energy & DOE Award with LabVIEW

By Nigel Kojimoto, CTO, and Marcus Lehmann, CEO, at CalWave Power Technologies

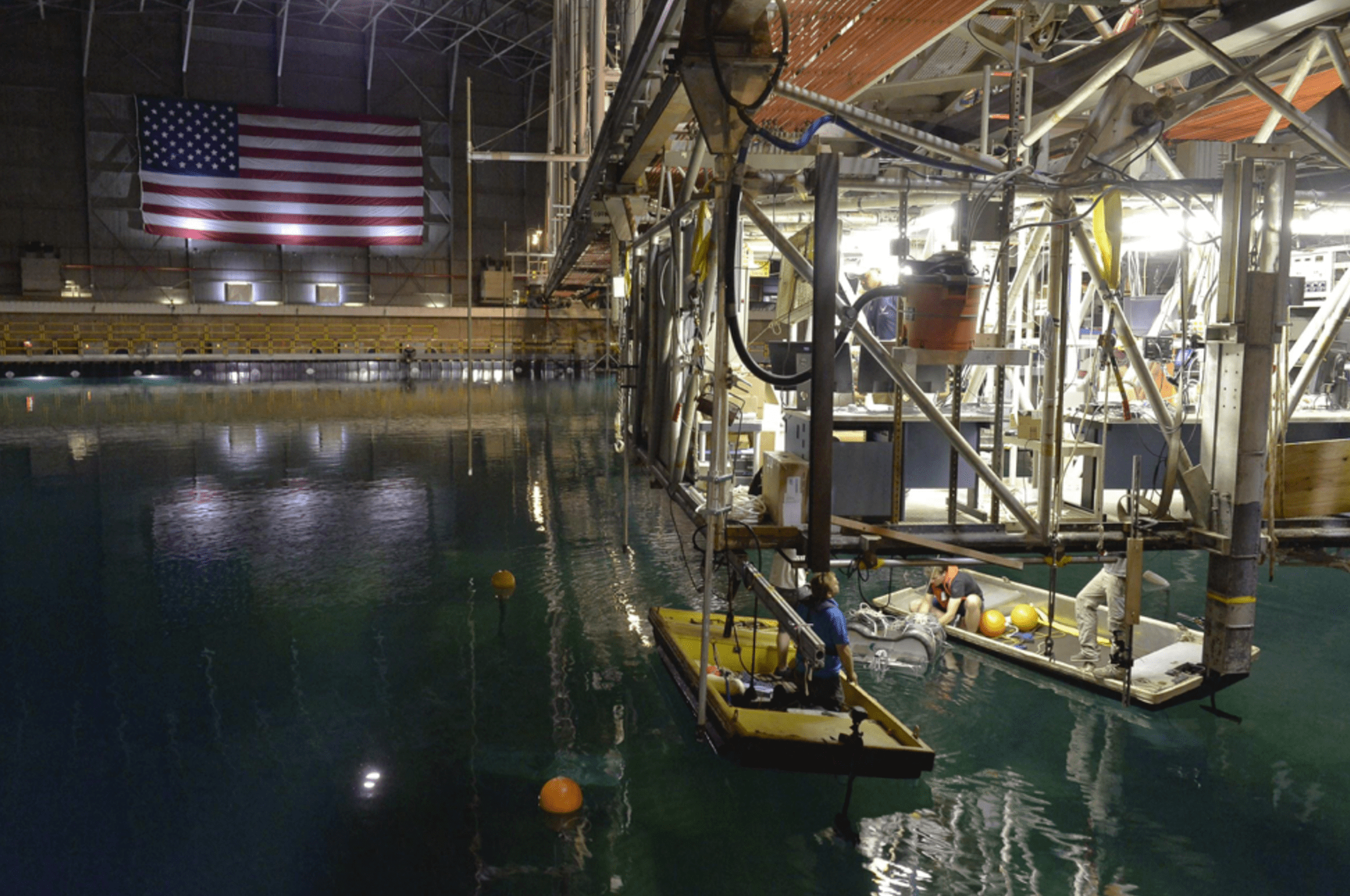

The CalWave Power Technologies team during prototype testing.

OBJECTIVE

Develop a 1:20 scale model of a wave energy converter (WEC) to compete in the Department of Energy (DOE) sponsored Wave Energy Prize competition.

APPROACH

Develop a novel subsea WEC using NI LabVIEW and NI data acquisition hardware by leveraging the expertise of JKI, one of our key sponsors.

HARDWARE & SOFTWARE USED

- NI LabVIEW System Design Software

- JKI State Machine system software templates

- NI cDAQ 9184

- NI 9205 Analog Input Modules

- NI 9401 Bidirectional Digital I/O Modules

- NI 9263 Output Modules

HIGHLIGHTS

- Developed our system in just 4 months

- Exceeded the DOE’s goal of cost-efficient wave energy extraction with our device by a factor of 3.6x

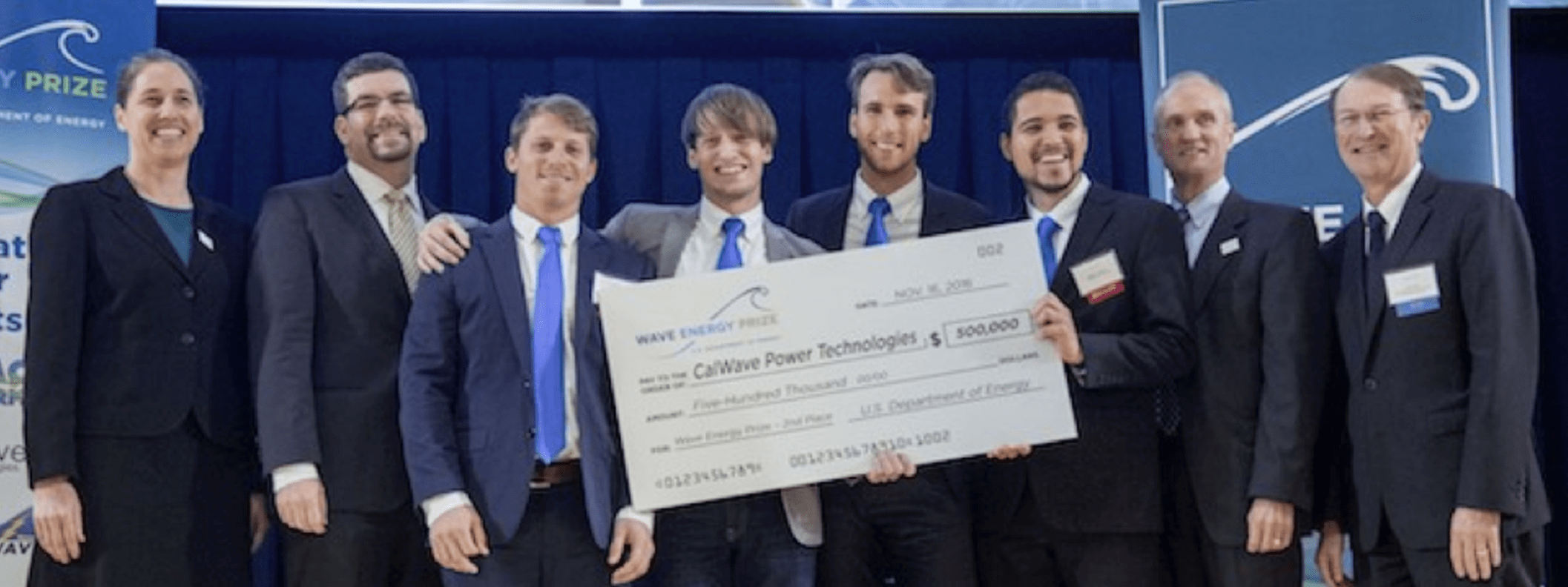

- Earned second place and $500,000 in seed money at the DOE’s Wave Energy Prize competition

According to the U.S. Department of Energy (DOE), ocean waves are a renewable energy resource with the potential to power more than 100 million US homes -- yet they are completely underutilized in today’s energy market. Wave energy has many advantages compared to other renewable energy sources (e.g. wind and solar): greater predictability, steady day- and nighttime availability, and significantly higher energy density (with an average of ~30 kW per meter coastline). As part of their effort to advance and accelerate the development of feasible and cost-efficient wave energy conversion technologies, the DOE sponsored a multi-year Wave Energy Prize, a public technology competition with over $2 million USD in prize money. A diverse group of organizations competed to build the best Wave Energy Converter (WEC) in terms of both wave absorption efficiency and cost-effective design.

Our team at CalWave Power Technologies, a startup coming out of the University of California at Berkeley, entered the Wave Energy Prize competition with a vision to develop a novel, scalable solution to wave energy conversion. Our solution was inspired by the ability of a muddy seafloor to completely absorb the energy of passing waves within only a few wavelengths. Waves seem to “disappear” when travelling over a muddy seafloor because the wave energy is dissipated, as the mud moves with and resists the motion of the wave. Our patented WEC solution features an optimized absorber body, to mimic the muddy sea floor, connected to a grid of controllable power takeoff units, consisting of double-acting dampers to extract the wave’s energy. Unlike many of our peers’ technology that extract wave energy at the ocean surface, our system operates fully submerged and out of sight. This unique approach enables several improved operating abilities: it can survive stormy seas; it causes no visual pollution; and it allows for precise control of structural loads because it does not have to manage the broad spectrum of wave loads typical of the ocean’s choppy surface.

First proof of concept of the initial WEC idea leading to CalWave’s award winning device

CalWave Power Technologies was one of 92 teams to enter the Wave Energy Prize competition. Based on our design proposal, the DOE selected our team as one of 20 semi-finalists. Results of our small-scale experiments and simulations then enabled CalWave Power Technologies to enter the final round to compete against eight other teams. As a finalist, we were given $125,000 in seed money and four months to build a fully functioning 1:20 scale prototype for the final competition. This was a very aggressive schedule, so we knew we needed to move quickly.

A Race to the Final Competition with No Time for Mistakes

The final competition for the Wave Energy Prize would consist of performance and load testing at the Naval Surface Warfare Center’s Maneuvering and Seakeeping (MASK) Basin in Maryland. Each team’s WEC would be subject to a variety of 45-minute test scenarios. If a team’s WEC structure, data acquisition, or device communication were to break down at any point during the testing, the entire test would not count toward the team’s score and would lead to significant time loss that could otherwise be used for performance tuning between tests. We knew we needed to extensively pre-test our system before the final competition to ensure that our system and its software and data acquisition hardware were extremely reliable. The need for this additional level of testing made our schedule even tighter. After all functional components of the prototype were defined and ready, we would have only four weeks to create the LabVIEW software and get the system up and running.

Readying our 1:20 scale WEC for the final tests in the DOE competition at the US Navy’s MASK wave basin

The stakes were high and the timeline was tight. To achieve our goals, we would have to move quickly -- and we could not afford to make any mistakes. We decided to seek sponsorship and guidance from industry experts who could accelerate our development and help reduce our risk of failure. We turned to JKI because of their expertise in using LabVIEW to help scientists and engineers get innovative technology to market quickly and reliably.

LabVIEW, NI Hardware, and the JKI State Machine: A Winning Combination

In just a few days, JKI’s engineers were able to understand our system requirements and provide us with a powerful LabVIEW template for our system software based on the JKI State Machine. The JKI State Machine is an easy-to-use yet powerful state machine template for LabVIEW that their team of experts has spent years refining. JKI also helped us select the best NI data acquisition hardware for the rapid development of our control and data acquisition system.

JKI engineers aren’t just experts in programming, they are very connected to the real world and how the code they develop will function in practical applications, which enabled us to exceed the boundaries of current state of the art technologies

Nigel Kojimoto - CTO at CalWave Power Technologies

We selected the NI cDAQ 9184 modular Ethernet chassis for our data acquisition system to allow our signal conditioning to be very close to the sensors, while still allowing our user interface software to communicate over the network. We selected the NI 9205 analog input module for acquiring our load sensor signals (force) and used the NI 9401 bidirectional digital I/O module for acquiring encoder signals from our linear position sensors (displacement, i.e. velocity), enabling us to continuously measure the power extracted from the waves via the power takeoff units (force times velocity). Finally, we selected the NI 9263 output module to provide analog closed-loop control of the system to optimize our power conversion performance.

The CalWave Power Technologies team receiving the Second Place Prize

With JKI’s expert guidance and training on the JKI State Machine and system software architecture, our team was able to quickly and easily customize the code to meet our evolving needs. We ran into a few system hardware hurdles along the way, and JKI was always there to help us quickly overcome these challenges. In the end, we delivered our completed system on time and ready for the competition -- and we won second place. CalWave Power Technologies received $500,000 to further advance and scale our technology, which will help us bring renewable wave energy into the mainstream. We couldn’t have done it without JKI, LabVIEW, and the NI data acquisition platform.

calwave.org

JKI is a National Instruments Certified Silver Alliance Partner.