If you’re a scientist or engineer at a high-tech company, you know that a key to business success is being able to quickly get innovative ideas prototyped and developed into a viable product for the marketplace. To do this, you need to be able to quickly and gracefully adapt to changing requirements and evolving technology.

In order to achieve this speed and flexibility of development, many of the top scientists and engineers are using Field Programmable Gate Arrays (FPGAs) for their prototypes and products. FPGAs are integrated circuits that promise:

- High-speed of execution

- Parallelism and determinism

- Flexibility of configuration after manufacturing

- Industrial-strength reliability

In my work as an embedded systems architect at JKI, I’ve seen the huge difference FPGAs have made to many of our customers in a variety of different industries, including semiconductor, medical devices, biotech instrumentation, automotive, and beyond. FPGAs have been a key success factor in getting their products to market with speed and impact.

ASICs or ICs: no customization or complex, long iteration times

Historically, if you wanted to run deterministic algorithms at high speed (e.g. not on a microcontroller with an operating system), one had the following two options:

- Find an Application Specific Integrated Circuit (ASIC) - An ASIC is a chip designed by someone else for doing a common, general-purpose task (e.g. PID control, signal processing, etc.). Unfortunately, you can't customize any of the functionality.

- Design Custom Hardware or Integrated Circuits (IC) - Designing a custom complex IC requires advanced design skills, a high cost per production run, and long lead times for changes.

Neither of these two options are well suited for the rapid iteration required for prototyping or small volume products (where economies of scale do not come into play).

FPGAs: flexible, affordable, short iteration times

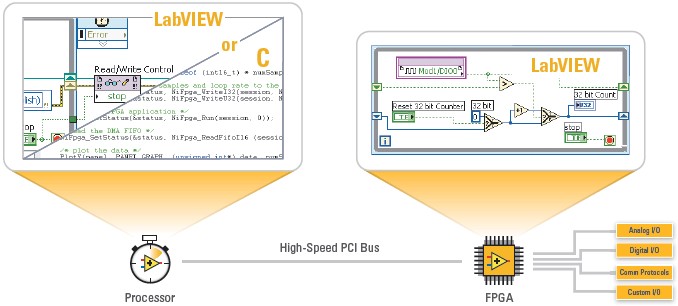

My first encounter with an FPGA was in a digital electronics course in college many years ago. This amazing computing device was an IC whose behavior could be reprogrammed on the fly! Still, programming FPGAs was time consuming, requiring one to use low-level hardware description languages and have specific knowledge on how to configure hardware.

Today, programming an FPGA can be as simple as writing control and signal processing algorithms in the LabVIEW visual data flow programming language. Additionally, National Instruments has a modular hardware platform, allowing FPGAs to easily interface with analog and digital signals; a variety of different sensors and actuators; cameras, motors, encoders, strain/pressure/force gauges; and industry-standard hardware communication buses like GigE, ethercat, CAN, I2C, SPI, modbus, etc. It’s no wonder why scientists and engineers are using this platform to innovate in nearly every imaginable application domain.

At JKI, our team works with FPGAs almost every day and we see them playing a key role in many of our customer’s projects including scientific instrumentation, energy storage and distribution, semiconductor test and metrology, and automotive applications. We’ve been very impressed with the results we’ve had and so have our customers. We’ve helped dozens of companies get hundreds of systems and products to market faster than their competitors.

One great example on which I worked as part of the JKI team is a grid-scale energy storage system that uses FPGAs for executing complex, high-speed algorithms for electrochemical battery process control and electrical power regulation. In this product, the FPGA-based solution allowed for extremely short development iteration cycles, making it possible to go from prototype to a shipping product in a fraction of the time when compared to other alternatives. Our solution won two NI Engineering Impact Awards at the NIWeek 2015 conference and it's having a real impact in the renewable energy industry.

As you can see, FPGAs can make a real difference to a company’s R&D efforts. The high-speed execution of parallel and deterministic algorithms provides better performance than other optional technologies; and the flexibility of configuration of FPGAs allows for iterating and improving algorithms as applications evolve, while quickly getting innovative ideas prototyped and developed into viable products for the marketplace.

I would love to hear about your project and your comments/questions about how FPGAs get innovative science and technology to market fast. Please post a comment below or connect directly with me on LinkedIn.