- RADX CASE STUDY

Creating a Modern Touchscreen User Interface for RF Test Systems with LabVIEW

By Ross Q. Smith and Robert ''Wade'' Lowdermilk, RADX Technologies Inc.

OBJECTIVE

Create a polished, intuitive touchscreen user interface in LabVIEW for controlling our LibertyGT 1200B PXIe multifunction wireless test system on a highly aggressive schedule.

THE SYSTEM

Software: LabVIEW and NI TestStand with RADX Real-time Measurement Science Software Hardware: RADX custom enclosure and NI PXIe system

- Unique hinged front panel

- HD touchscreen display

- LibertyGT RF Interface Unit (RFIU)

- NI PXIe Embedded Controller

- NI FlexRIO FPGA module

- NI Digitizer/oscilloscope module

- NI Digital multimeter (DMM) module

- NI Analog input module

- Crosspoint matrix switch module

Key Software Feeatures:

- Intuitive workflows that display the most commonly used functions for a particular task

- Sophisticated UI assets developed in Adobe Photoshop

- Smooth screen animations and visual feedback to confirm user input

- Easy-to-use Help button that plays integrated video tutorials

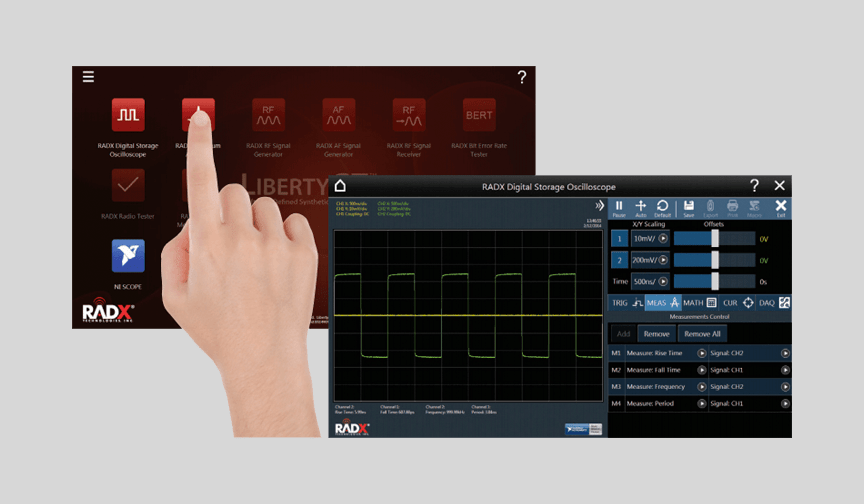

JKI designed a unique ''home screen'' framework for launching and managing different virtual instrument applications, just like a smartphone or tablet.

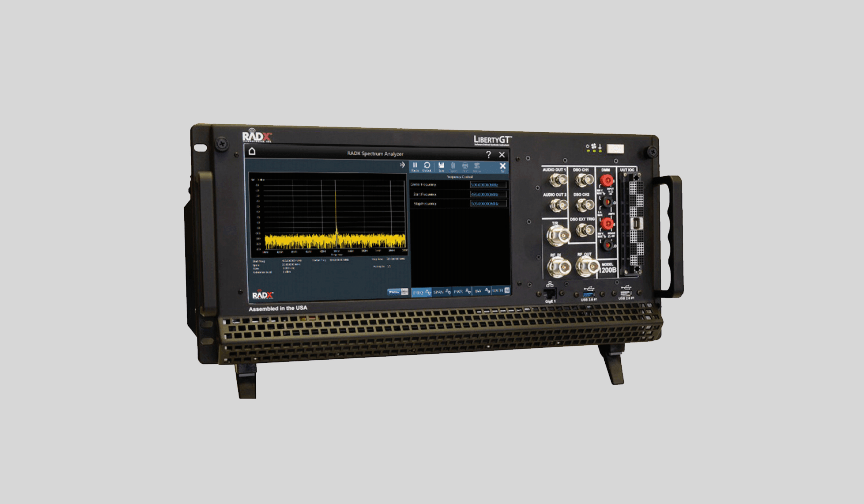

A Modern Display for a Modern RF Test System

Our company, RADX Technologies, is a small, fast-growing startup that has developed a revolutionary new approach to microwave, RF and wireless communications test systems. We created a modular, COTS instrument called the LibertyGT 1200B (LGT1200B) that, through the power of LabVIEW software, can be reconfigured to run multiple measurement instrument personalities at the same time. Until now, RF system and wireless device testers have assembled labs from multiple different devices, all of them difficult to program and expensive to upgrade. The LGT1200B allows these system designers to save lab real estate and reduce cost, while increasing flexibility and programmability of their equipment.

We had a big industry trade show coming up and knew our prototype LabVIEW software and user interfaces (UIs), which came from a desktop environment, weren’t designed for and certainly weren’t easy to use on the LGT1200B’s 11-inch touchscreen display. We urgently needed the help of a highly experienced LabVIEW engineering team to transform our prototype software into something that would work and look as amazing as our system and RF measurement science technology.

We needed a team with unequivocal skills in LabVIEW UI development who would work well with our team of measurement science experts, and we found that in JKI. The JKI team is efficient, professional, and worked aggressively to deliver a superior product in a six-week timeframe.

Ross Q. Smith - RadX Technologies, Inc.

LabVIEW UI Experts Deliver Modern Touchscreen Interface in Just 6 Weeks

After seeing demonstrations of JKI’s existing work creating highlypolished touchscreen UIs for LabVIEW applications, we quickly realized JKI had the deep LabVIEW programming expertise and user experience know-how to transform our prototype into a professional, customer-ready product with the fastest time to market. With less than two months to go, JKI was unfazed by our aggressive schedule and immediately flew out to our company site to kick off the project and conduct in-person interviews to thoroughly understand our business goals, team structure, and software architecture.

Our UI prototypes were made using default LabVIEW controls and indicators, which are intended for mouse and keyboard usage. JKI understood that for a touchscreen experience, the marketplace expects the look and feel of modern-day smart devices running applications. JKI designed a unique “home screen” framework for launching and managing different virtual instrument applications, just like a smartphone or tablet— including the ability to add third-party measurement science applications. They also updated two of our applications for touchscreen compatibility.

Given the short six-week timeframe, we sent our European R&D team to JKI’s office in California to work side-by-side with their engineers. We had great synergy with JKI, and their expertise in LabVIEW architecture, performance, and UI development was very complementary to our expertise in measurement science. JKI truly felt like an extended part of our team, due in large part to their ability to relate and communicate well with our diverse group. Having both engineering teams in one location allowed us to deliver a superior end product, ahead of schedule. Customers and prospects love the extensive functionality, professional design, and easy usability of the new LGT1200B.

An Investment That Continues to Pay Off

JKI did more than just make a “pretty” interface; they worked closely with our executive and technical staff to really understand our overall business goals and create a custom solution that perfectly fits our end users’ needs. Plus, since JKI’s software architecture is very modular and scalable, we can easily reuse and develop additional applications on our own, extending the product’s capabilities over time. For companies that need a state-of-the-art UI experience delivered in a short amount of time, we definitely recommend JKI as the premier experts in LabVIEW development. Their entire team works efficiently and aggressively to meet deadlines, and the high quality results are well worth the investment.

555 Bryant Street #349

Palo Alto CA 94301

619.677.1849

radxtech.com

JKI is a National Instruments Certified Silver Alliance Partner.