- PROTEUS CASE STUDY

Pioneering Intelligent Medicine with JKI

By Gary Palmer, Staff Electrical Engineer, Proteus Digital Health, Inc.

OBJECTIVE

Create a collection of component and system testing tools to manage system verification and production testing for our Intelligent Medicine system, which helps patients better understand and manage their health.

THE SYSTEM

- NI LabVIEW 2009 for Windows

- DAQ: NI USB-6501 module

- Keithley 2400 SourceMeter

- Keithley 2000 Multimeter

- Embedded firmware programming interface (SPI bus)

- Customer custom-built DUT test fixture

- Windows Bluetooth interface

Changing Healthcare Through Intelligent Medicine

Proteus Biomedical develops intelligent medical products based on body-powered and implantable technologies. These technologies enable intelligent pharmaceuticals and more capable implantable devices.

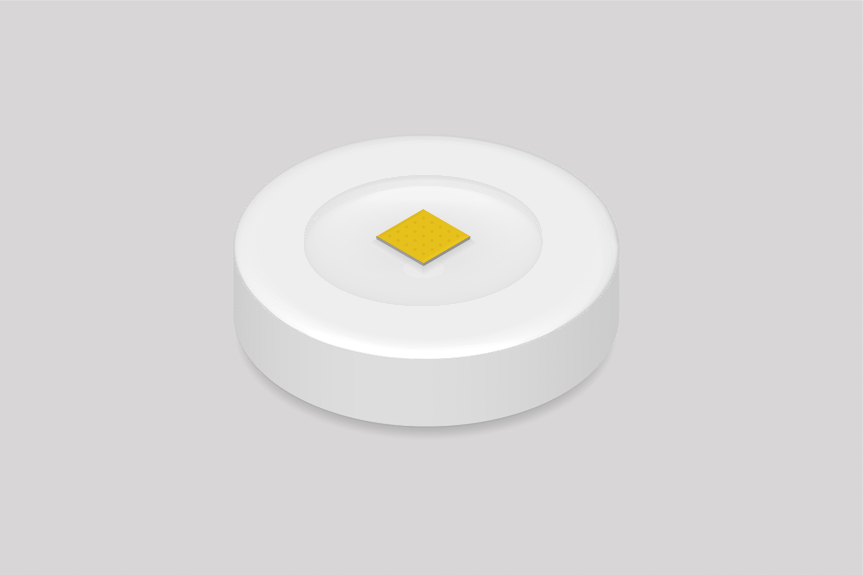

One amazing technology under development at Proteus is our unique Raisin™ system. The Raisin system combines an intelligent pharmaceutical (a pill with a sensor) with a wearable monitor. The intelligent pharmaceuticals are enabled by ingestible event markers (IEMs): tiny, digestible sensors made from food ingredients, which are bonded to a patient’s pills and activated by stomach fluids after swallowing. Once activated, the IEM creates an ultra-low-power, private, digital signal detected by a microelectronic recorder (a personal monitor) worn as a small bandage-style patch on the patient’s skin.

The Raisin patch personal monitor records information such as type of drug, dose, and place of manufacture; captures date and time; and also measures and reports physiologic parameters such as heart rate and activity. The collected data can also be used to derive metrics like sleep patterns and respiration rate. The patch communicates with the patient’s phone using Bluetooth, and the phone makes the data available to doctors and patients via user-friendly customized displays on mobile phones, tablets and desktop computers. By providing the ability to accurately capture medication-taking behavior and link it to the related physiologic response, we create a powerful information set that can help patients better understand and manage their own health. This information is also invaluable for physicians and family caregivers as they look after their patients and loved ones.

Required: Rapid Product and Test Development

In support of our product development efforts and our regulatory submissions, we needed resources to accelerate the development of verification tools. We specifically needed significant additional LabVIEW expertise and we needed a team that could come up to speed quickly.

JKI came highly recommended by our Raisin product manager, who had worked with them at a previous company. We had also used their team for a complex project in a different area in the past. The quality and timeliness of their work for this previous project were exemplary. JKI had delivered on time previously, so we were confident we could trust them with the Raisin project activities.

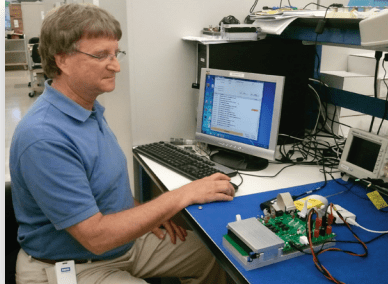

Building and Testing Raisin System Components with JKI and LabVIEW

JKI worked with us on a variety of applications for the Raisin system:

- Bluetooth link between the patch and a phone: As a part of the Raisin development effort, we needed to create a PC-based Bluetooth application to accelerate the system development in parallel with the phone application work. We worked with JKI to produce this application. The application gave us a fast and effective way to perfect the patch’s communication, and LabVIEW provided an ideal environment for developing this application.

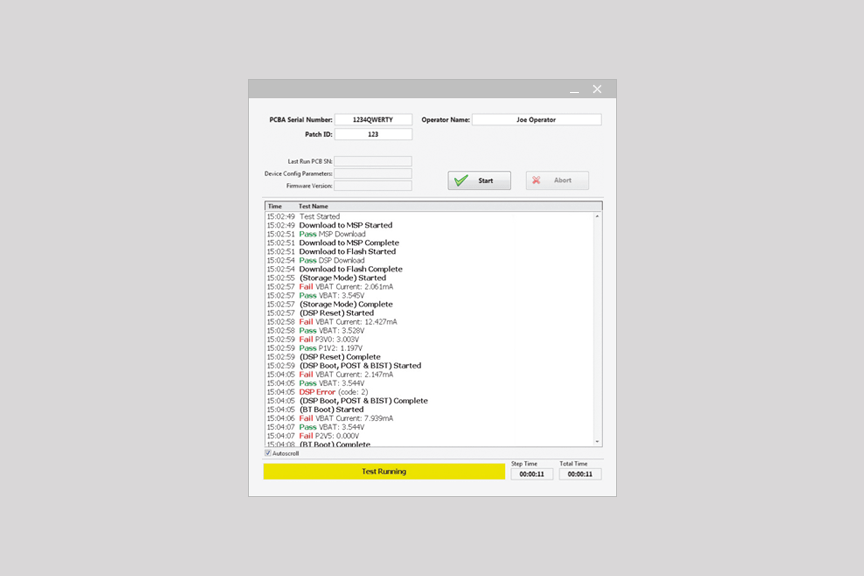

- Bluetooth manufacturing application: As a part of the manufacturing process, we needed an application to communicate with the patch via Bluetooth for testing and programming. JKI built a LabVIEW-based system that allows us to perform a number of operations via Bluetooth after manufacturing. One specific example is a test of the Bluetooth link. They wrote an automated test application for manufacturing that was very easy to use: operators press a few buttons, and all Pass/Fail test data is automatically captured in a file.

- IEM test application: JKI also created an IEM production test tool to be used at the end of the manufacturing line to verify product function.

Ongoing System Improvement

Based on the success of our past development collaboration, we are currently using JKI for the development of the test systems for our next generation patch personal monitors. As always, this work is on a very tight timeline and we are confident that the outstanding team at JKI will deliver as promised.

We also have high confidence in the quality of the material that JKI produces. The code they deliver works. When JKI makes a promise about a timeline, we know we can trust it.

We have a lot of respect for the JKI team. We enjoy working with them and have built a great relationship. The JKI engineers integrate well with our team and have really become a part of it. I would absolutely recommend them to other companies who need custom product development. They are a top-notch team that you can trust to deliver high quality work on time.

2600 Bridge Parkway

Redwood City, CA, 94065

650.632.4031

proteus.com

JKI is a National Instruments Certified Silver Alliance Partner.